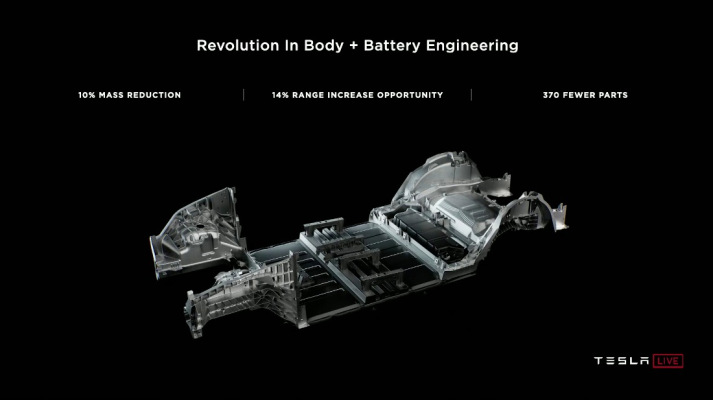

Tesla has fundamentally redesigned the way that its battery packs integrate into their vehicles, turning them into structural elements of the car, rather than just fuel sources on their own. At Tesla’s Battery Day event on Tuesday, Elon Musk compared this to how commercial aircraft used to load fuel into tanks that were contained within the wings, but that were essentially bolted onto internal structure — later on, they realized much greater efficiencies in how much fuel could be carried, as well as weight and parts usage, by making the wing bodies actual fuel tanks themselves.

“All modern airplanes, the fuel tank, your wing is just a fuel tank and wing shaped,” he said. “This is absolutely the way to do it. And then the fuel tank serves as dual structure, and it’s no longer cargo. It’s fundamental to the structure of the aircraft — this was a major breakthrough. We’re doing the same for cars.”

By turning the battery cell into a structural component of the vehicle, Musk pointed out that they can actually save more mass overall in the car than you would assume on paper if you just took out the structural supports in the battery cells as they currently exist. That’s because the battery itself is doing a lot of that support work — which, he points out, actually makes the overall vehicle safer, which might seem counterintuitive.

Tesla will achieve this by creating a filler that is also a structural adhesive, and that also acts as a flame retardant. It “effectively glues the cells to the top and bottom sheet, and this allows you to do shear transfer between upper and lower sheets,” Musk said.

“This gives you incredible stiffness, and it’s really the way that any super-fast thing works is you create basically a honeycomb sandwich with two phase sheets,” he said. “This is actually even better than what aircraft do because they can’t do this because fuel is liquid.”

The end result of this will be that a structure that enables Tesla’s cars to be much stiffer than any regular cars. That stiffer design is better for safety overall, and also means that the batteries will be more efficient, while also avoiding any “arbitrary point loads” of strain or stress on the battery cell itself.

“It also allows us to use to move the cells closer to the center of the car, because we don’t have […] sort of all the supports and stuff,” he said. “So, the volumetric efficiency of the structural pack is much better than a non-structural pack. And we actually bring cells closer to the center.”

This reduces the potential of side impacts from collisions actually reaching the cells, which means they should be less susceptible to sustaining the kind of damage that can result in battery-related fires. It will also “improve the polar moment of inertia,” Musk said, which basically translates to better overall maneuvering of the vehicle and driving and handling feel.

Finally, there are 370 fewer parts in the structural battery design versus the current Tesla battery cell design, which greatly reduces cost as well as potential failure points. That’s going to add up to a lot of manufacturing savings, per Musk, and will stack with the other battery innovations he unveiled.